Product

PRODUCT

- car lifts

- car washing machine

- tire service machine

-

spray paint booth

-

pneumatic dust-free dry sanding machine

- flushing machine

-

car battery

-

equipment solution

- car jacks

-

auto collision repair system

-

Oil Collecting Machine for car

-

exhaust extraction system

-

Shortwave Infrared Curing Lamp

-

General equipment and tools

- -Wheel Chocks

- -Hydraulic Ram

- -Nylon Wheel

- -Rubber Jack-Pad

- -working lamp

- -Work gloves

- -Paper

- -training system

- -sweeper

- -vacuum cleaner

- -Air compressor

- -car repcord

- -Tool Car

- -Tie Down/Tow Strap

- -Air Tools Combo Kits

- -Automotive spray booth

- -Grease Gun

- -High Pressure Washer

- -Compressor washer

- -Air gun

- -Car polisher

- -Pipe Bender

- -Parts washer

- -Paint Stand

- -welding machine

- -booster cable

- -hose reel

- -Chain Block

- -car seats

- -Car Dolly

- ungrouped

Features

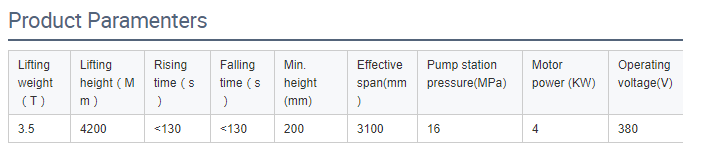

1.General

auto lifter is a hydraulic & transmission type auto lifter developed by our company. The lifter body is welded up with profile steel, novel and endurable. Special safety device against chain breaking is installed to ensure safe and reliable operation. This lifter features simple operation, stable running, low noise and wide range of application.

2. Usage:

This machine is suitable for lifting the Cars, light station wagons, vans and other light vehicles with the self-weight below 3000kg.It can lift the autos to the required level for maintenance.

3. Construction

This product mainly consists of posts, tray,transmission beam, chain safety device,oil cylinder,hydraulic pump station,etc.To raise the lifter, just press motor button. To lower down the main unit, toggle down the handle of the manual directional control valve at the pump station to unload oil cylinder and lower down the tray.

4. Safety Device

double chain drive,one working chain,and the other is safety chain,when the working chain is broken,then safety chain will work.

5. Operation of lifter

5.1 Drive the vehicle onto the tray and block the wheels with cushion wood.

5.2 Pull the switch of claw clips to the off position,lay down four claw clips on both ends of the lifting beam to ensure the tray is secured during rising.

5.3 Rising: switch on the power and press the pump station button and the lifter begin to rise up. When reaching the required height, the trip switch control, automatic shutdown.

5.4 Falling down:

when falling the lifter, First pneumatic control of insurance to the open position knob pull to disconnect the claw clip with the plate clip, than toggle down hand-operated directional valve at pump station to cylinder unloading ,then fall down the tray.

6. Precautions

6.1 It’s strictly prohibited to walk under the lifter when it’s going up and down.

6.2 It’s not recommended to raise the lifter to the limit of the height to avoid excessive pressure at pump station.

6.3 All the things under the tray must be cleared off before the vehicle goes down.

6.4 The safety claw clips must be secured when servicing the vehicle.

6.5 Keep the working environment clean.

6.6 Add grease at the lubrication points at least once every week.

6.7Hydraulic oil tank should bear the weight and 14 liters of 30 # hydraulic oil, less than 13 liters should be added

6.8The user should contact the dealer or manufacturer at once for specialists for any problems that he can’t solve.

7. Installation:

The installation steps as follows:

7.1 The equipment should be installed on vibration-free and solid concrete foundation.

7.2First four columns bolted to the chassis, and then installed, then fixed on the ground on the chassis, and should be kept vertical.

7.3 The transmission beam bolted to the top column.

7.4 Fix the tray and lifting beam.

7.5 Connect the chain.

7.6 Fix the hydraulic station on the back of a post, and connect the oil pile. Fill up the oil tank with 30# hydraulic oil.

7.7Apply lubrication grease on chain and rollers.

8. Test run

8.1 Pre-test inspection: should carry our an overall inspection before test run to check whether the fastening parts, connection parts and hydraulic system fittings are tightened up, whether the power conforms to rating, and whether the motor’s rotating direction is consistent with that marked on the pump station.

8.2 No-load run: repeat the rising and falling for several times to observe whether the hydraulic system and its running parts are normal and whether it’s running normal when reaching the height limit.

8.3 Load run: repeat the rising and falling for several times to check whether the units are running normally. Only after test start with the lifting &service.

9. Maintenance:

9.1 Keep the machine clean: this machine should be cleaned regularly and kept clean. Wipe off the power before cleaning to ensure safety.

The machine work environment should be kept clean order, kept clean, such as work environment, more dust, mechanical wear will be accelerated, shortening their service life

9.2 Frequent inspection:

9.2.1Check Safety Insurance Agency:the safety device should be inspected frequently for whether it is sensitive and reliable. If the safety device is found abnormal, it should be adjusted, repaired or replaced.

9.2.2Check the chain:Should be inspected regularly to ensure good co-chain. If an inspection found the chain too loose or too tight, can be adjusted by adjusting the screw, but adjusted the screw and the cap should be tightened to prevent loosening.

9.3 Maintenance on hydraulic system:

9.3.1Cleaning, oil change:should keep the hydraulic oil clean. If the oil is not clean, should change with new oil to ensure the service life of the hydraulic parts. After running for the first three months for the machine initially filled with oil, should clean the system and change with new oil. Later change the oil once every six months.

9.3.2Replacement seals.